What are the key factors affecting workpiece quality during production?

While factors like equipment performance, raw materials, processing method and operator experience matter, one crucial element consistently influences the outcome:

In Additive & Subtractive Hybrid Manufacturing (ASHM), parameters are critical from design to final product. They play a crucial role, from the design of model data to the control of deformation during 3D printing, and finally to the strategy design in the milling process.

.jpg)

The accuracy of model data depends on the precise setting of various manufacturing parameters during modeling. Whether it’s the precision of modeling dimensions, the parameters and selection of supports, or even the placement of the workpiece, every minor adjustment can alter the final accuracy of the model data.

Printing deformation, an important indicator of the stability of the 3D printing process, is also influenced by manufacturing parameters. Precisely adjusting the parameters of the printing process, heat treatment process, and support process can minimize deformation during printing, ensuring the stability and consistency of the workpiece dimensions.

Milling, which has the greatest impact on the dimensional accuracy of the workpiece, requires careful parameter setting in the machining strategy. In milling, parameters like milling paths, depths, tool selection, and feed rates are essential for achieving precise dimensions.

Mastering these parameters is key to high-quality production.

In manufacturing, obtaining the optimal production parameters to achieve the best quality products is not an easy task. It often requires significant time, effort, and testing costs from the manufacturer, which greatly limits the widespread production of high-quality workpieces.

To address the conflict between production demands and technological limitations, Riton3D, a company with years of expertise in the laser and dental industries, will introduce a dedicated manufacturing parameter database as part of its new dental ASHM Solution.

This database will provide detailed parameters needed for both key stages of manufacturing—3D printing and milling. Each parameter has been rigorously validated by Riton’s R&D department to support the efficient production of precise dental workpieces. This will help reduce the cost of trial and error in manufacturing, enabling dental laboratories to more easily handle the processing requirements for multi-brand interfaces and various specifications of workpieces.

During the 3D printing parameter setting phase, users only need to select and import the parameter file from the database with one click to complete the configuration of printing process parameters and path planning that meet production requirements. This significantly reduces the time and effort required for the initial design phase of 3D printing, ensuring the precise stacking of each layer of material during the printing phase, laying the foundation for high-precision workpieces.

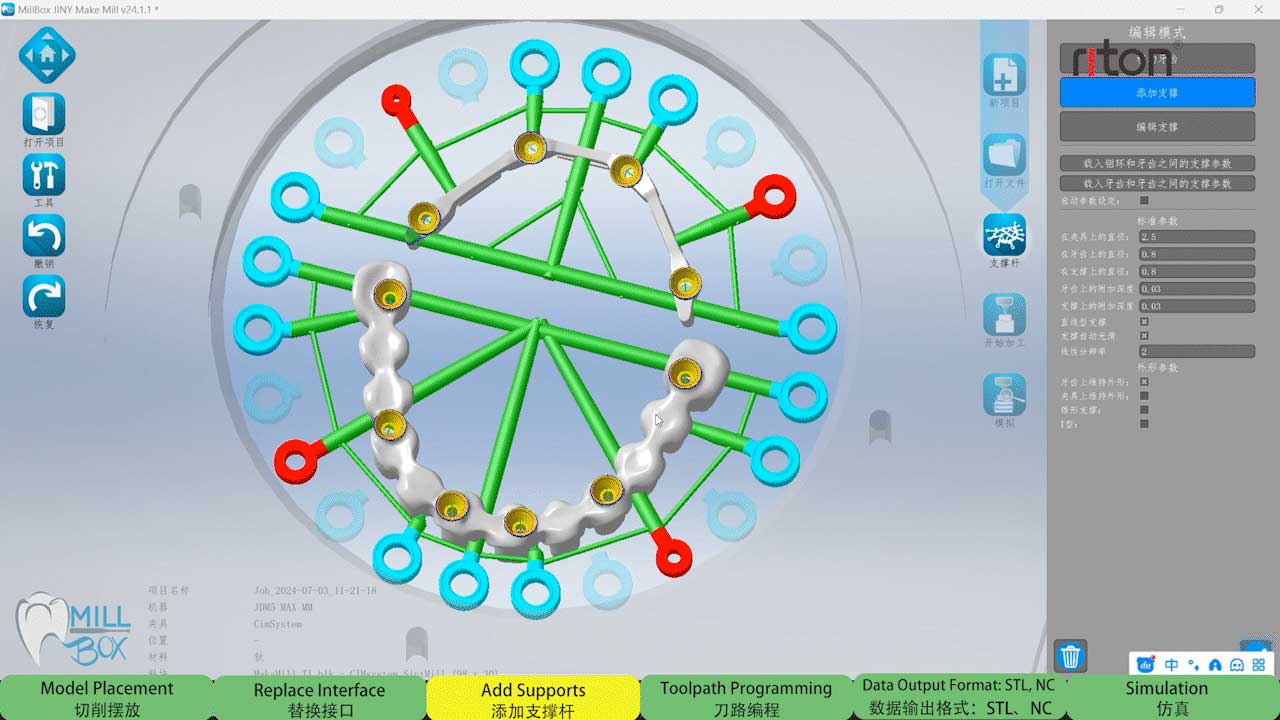

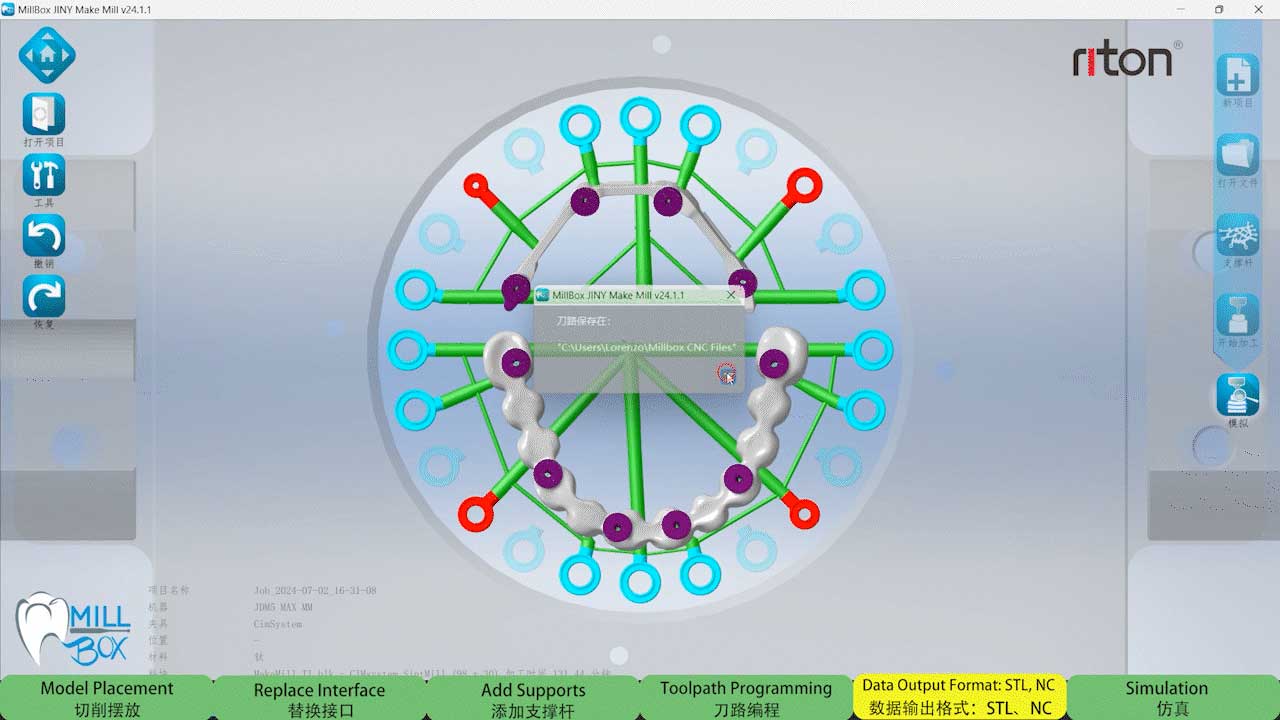

During the milling strategy design phase, the close collaboration between the specialized parameter database and Millbox makes the once complex operations unprecedentedly simple.

After importing the matching parameter data, Millbox takes only 15-20 minutes to complete the precise planning of the milling toolpath. The preview of the milling results gives users a more intuitive understanding and comprehensive control over the accuracy of the finished product, providing strong support for subsequent processing.

With a dedicated parameter database and intelligent software, Riton Dental ASHM Solution makes the manufacturing of dental precise workpieces easily achievable.

For more details, please fill in the information in the “Contact Us” section, or send your inquiries to our email: Marketing@riton3d.com.

Riton 3D Printers