Focus on the digitization innovation of additive manufacturing, work together to win the future together! The Formnext 2024 was held at Messe Frankfurt from November 19th to November 22nd, Germany time. Riton brought additive manufacturing digitization solution schemes in multiple fields and showed up at the exhibition, presented a grand meeting of technical innovation for visitors all over the world together with many leading enterprises in additive manufacturing.

Annual New Product Area: MLab showed Riton’s strength in technical innovation

As one of the annual new products that Riton launched, MLab, the desktop metal 3D printer whose main machine covers an area of only 0.36 m², attracted a lot of attention.

MLab’s outstanding printing precision and efficiency are coupled with the new control software Riton Controller which is independently developed by Riton won visitors’ praise and preference. It supports intelligent monitoring of the overall machine status, custom editing of the printing content, intelligent resume printing and other strong functions, showed Riton’s strength in technical innovation.

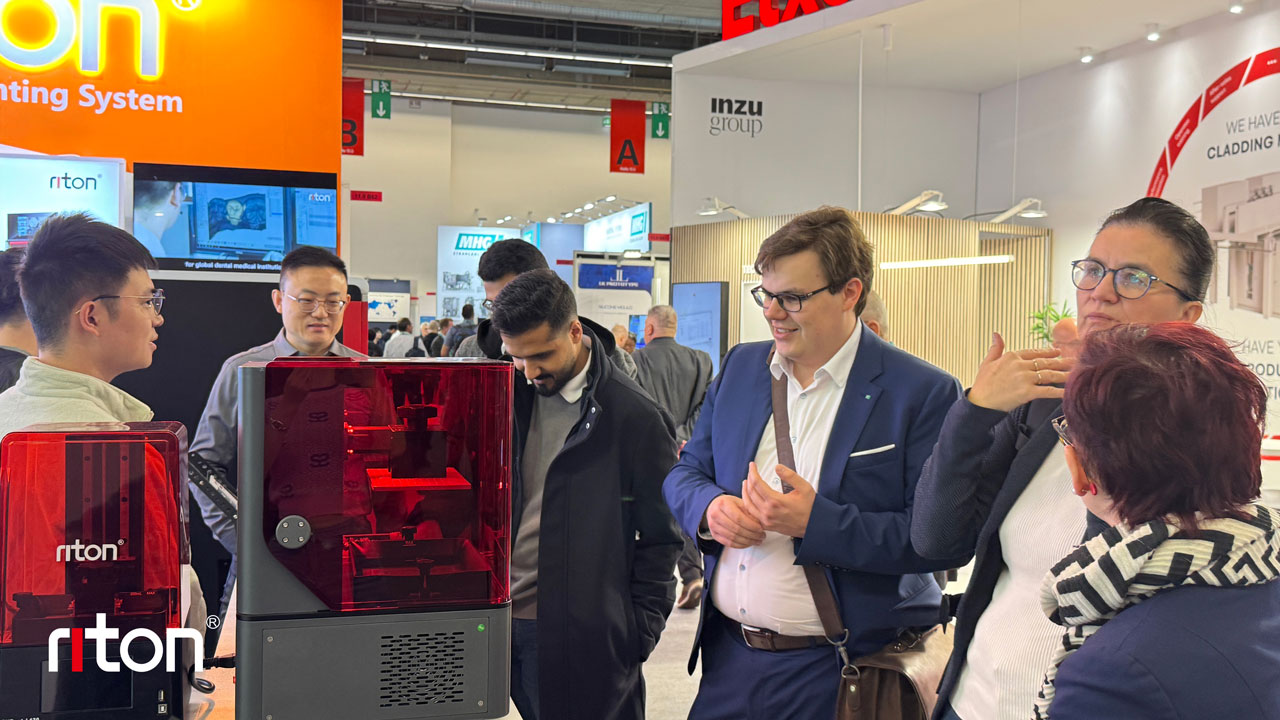

Classic equipment area: diverse choices met multiple needs

Riton classic metal 3D printing devices M-150 and Dual-200 were still star products in the booth.

M-150 is a lightweight, small metal 3D printer especially launched for limited space. Compared with a conventional metal 3D printer, M-150 achieves a “slimming” of the overall size, at the same time is comparable to a conventional metal 3D printer in terms of printing precision, efficiency and digital automation level.

DUAL-200 is a professional metal 3D printer designed for dental laboratories with the need of rapid production of big size parts or large volume production of fine parts. It is equipped with double fiber lasers and a huge square melting area of 150mm X220mm, provides dental laboratories with more flexible choices in terms of product printing precision and production efficiency.

Light Curing Area: built a new printing experience of high quality and efficiency

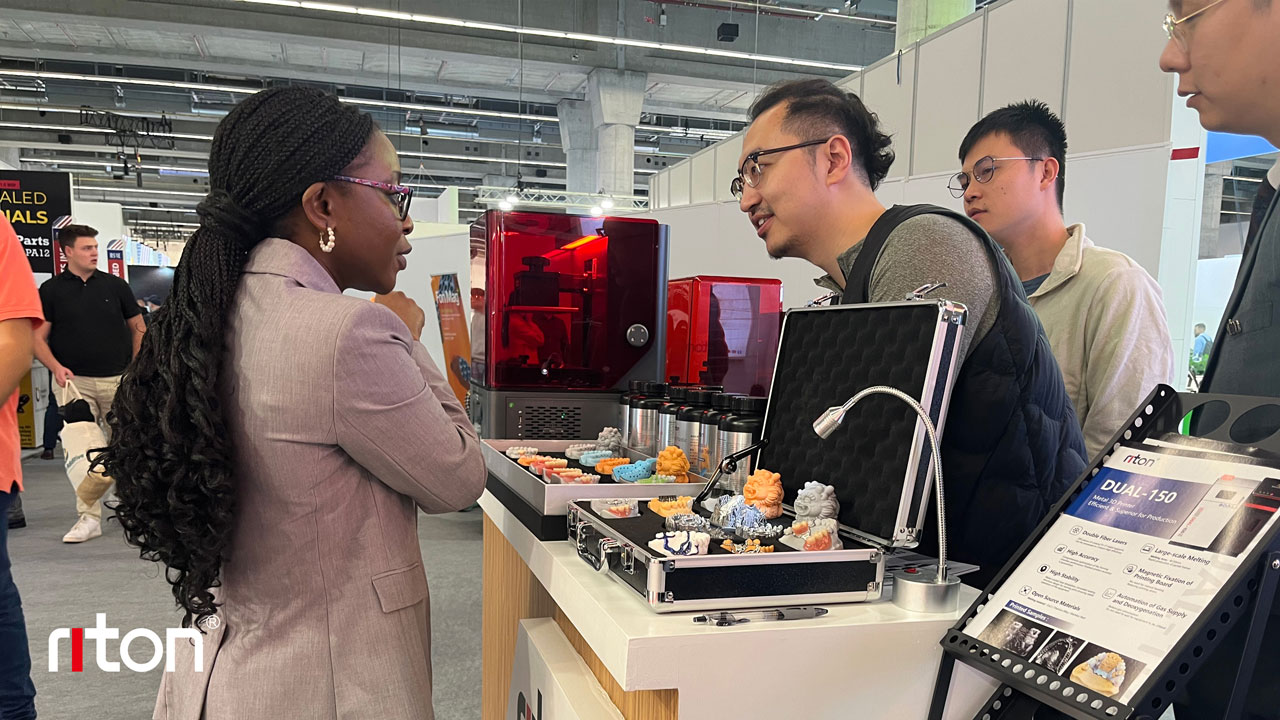

At the light curing area in Riton booth, RXDent-L series resin 3D printers and their supporting equipment were popular too. It only needed simple operation to achieve the high-efficiency and high-precision product printing, and the excellent interaction experiences amazed the visitors. They said that the technical innovation in light curing additive manufacturing dramatically improved the production efficiency and joy of creation.

The four-day Formnext 2024 came to a perfect end. During the exhibition, Riton showed the strength of Chinese intelligent manufacturing to visitors around the world, made in-depth communications with old and new cooperators and discussed more opportunities for cooperation. In the future, Riton will continuously deepen the field of additive manufacturing digitization, maintain the professionalism in 3D printing and bring more excellent equipment, consumable items and services for customers and the industry!

Riton 3D Printers