On April 29, 2023, the Guangdong Provincial Machinery Industry Science and Technology Award Ceremony was held in Dongguan, Guangdong. The project "Key Technologies and Industrialization of Personalized Custom Denture Laser 3D Printing," led by Guangzhou Riton Additive Technology Co., Ltd. in collaboration with the School of Information Photonics and Optoelectronics at South China Normal University, was awarded the First Prize of the Guangdong Provincial Machinery Engineering Society Science and Technology Award.

The Guangdong Provincial Machinery Industry Science and Technology Award is established and organized by the Guangdong Provincial Machinery Engineering Society, aimed at the entire provincial machinery industry. This award focuses on recognizing units and individuals that have made significant technological innovations and outstanding contributions to the machinery industry, achieving remarkable economic and social benefits, thereby promoting technological advancement in Guangdong’s machinery industry and enhancing the core competitiveness of the entire sector.

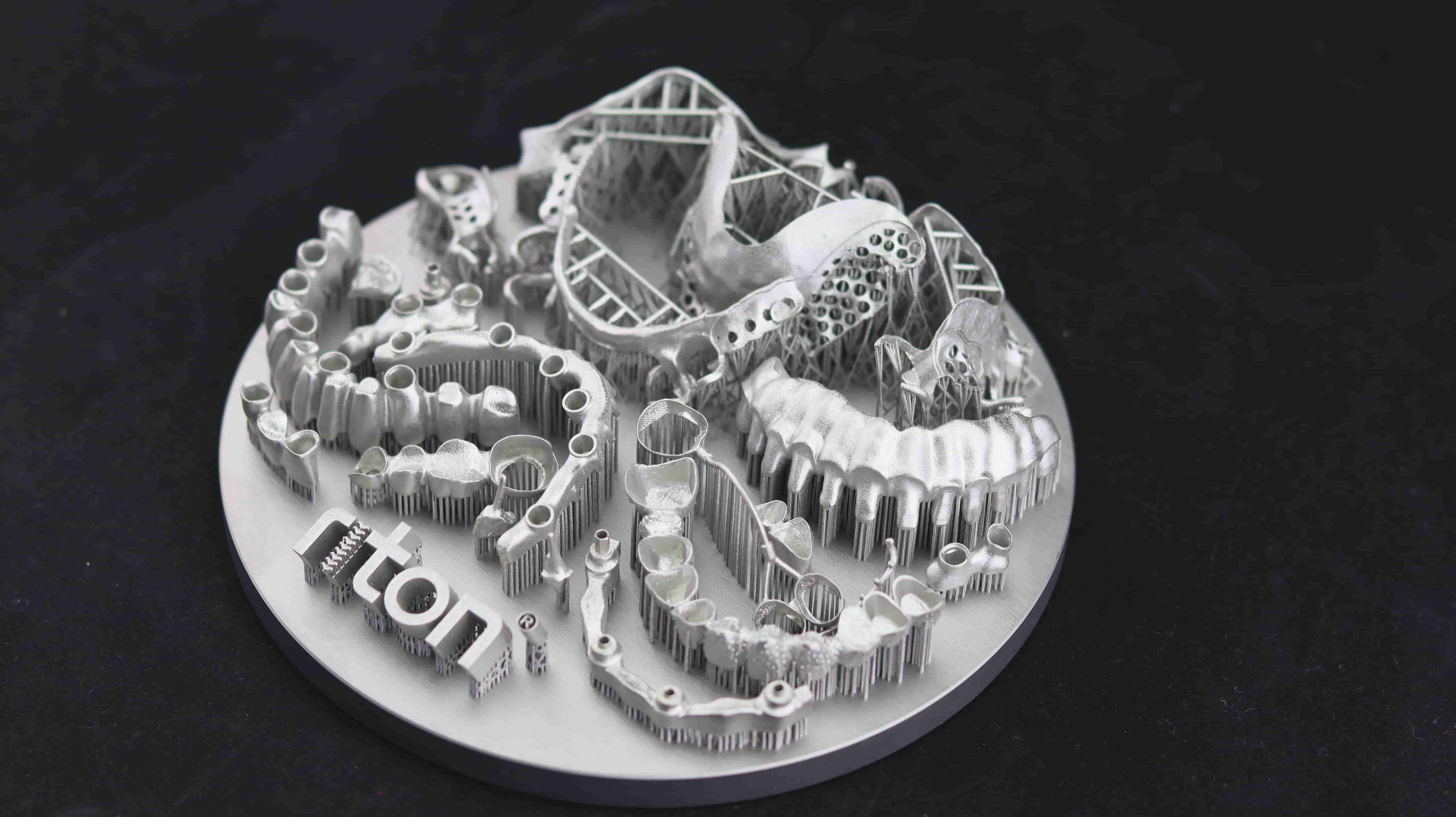

The awarded project, "Key Technologies and Industrialization of Personalized Custom Denture Laser 3D Printing," addresses the transformation and upgrading of personalized denture processing technology, as well as the demand for high-precision printed products. It employs principles from mechanical design, electrical control, software development, optical design, laser technology, and simulation, utilizing key technologies such as intelligent dual-loop oxygen content precise control, capability-compensating molding control, and a high-efficiency segmented variable-speed powder spreading system. This has led to the development of laser 3D printing equipment for personalized custom dentures, successfully applied in the denture processing industry.

Compared to traditional denture processing techniques, this technology shortens the process by 30%, reduces gas consumption by 30%, and improves efficiency by 50%. The surface of printed products is smooth, free from warping and residue, with an average error reduced to 0.015mm and molding precision of ±0.06mm, meeting the precision requirements for dental applications.

With high molding precision, efficient processing, excellent mechanical properties, and low operational costs, the personalized custom denture 3D printing technology developed by Riton promotes the digital transformation of the dental industry, laying a technical foundation for achieving a digital dental processing cloud platform and intelligent engineering. Its various advantages have garnered widespread recognition within the industry.

As of now, no literature has been found on domestic and international platforms that integrates the technological characteristics of Riton's project. Riton's advanced research achievements in the application of dental SLM technology will undoubtedly provide broader options for industry transformation and upgrading. In the future, Riton will continue to maintain its professionalism in 3D printing, continually enhance product and service capabilities, and provide high-quality equipment, materials, and services for clients and the dental industry!

Riton 3D Printers