Input Voltage | 220V |

Control Voltage | 24V |

Rated Power | 800W |

Overall Dimensions | 335x800x1650mm |

Weight | Approximately 70Kg |

Feed Speed | 60mm/s—120mm/s |

Feed Accuracy | ±0.02mm |

Bending Speed | 180°/s—300°/s |

Bending Accuracy | ±0.2° |

Consumables | 0.5mm—1.2mm orthodontic stainless steel wire |

Bending Efficiency | Within 60 seconds for conventional processed parts (such as double-curved archwires) |

Wire Change Efficiency (same specification wire) | Single-person operation time: approximately 2 minutes |

Capable of bending steel wires with diameters ranging from

0.5mm to 1.2mm

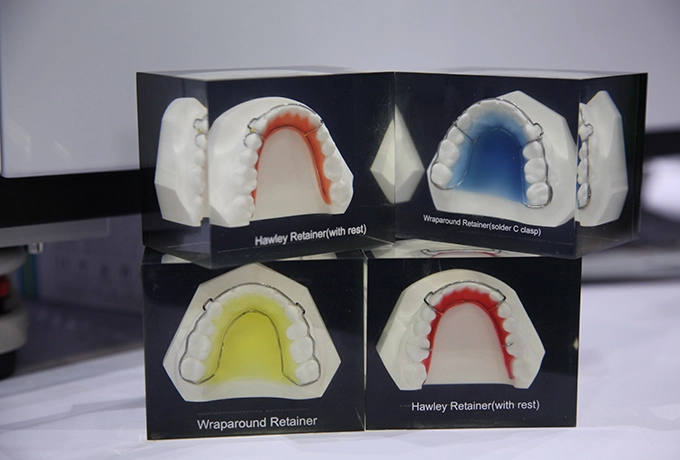

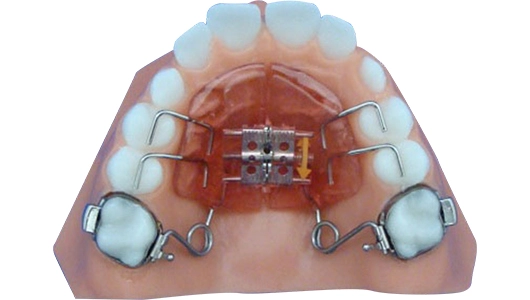

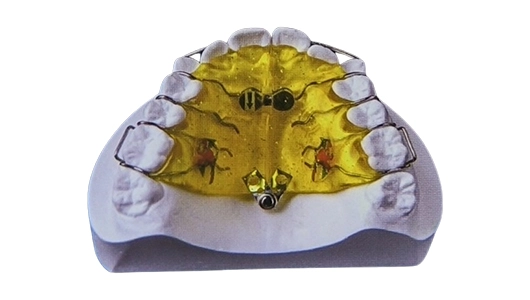

Suitable for the production of various types of

removable orthodontic appliance

<60 Seconds

Complete the bending of standard structural components

(such as Double-curved Labial Bow)

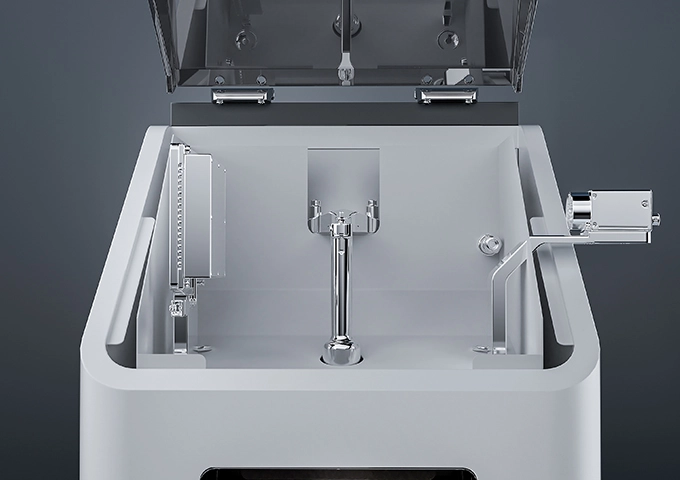

Specialized fixtures and straighteners combined

with a visual auto-calibration system

provide dual assurance, ensuring that the bending angle deviation of the final product is

≤±0.2°

The machine connects with the Riton Cloud & Riton Jawdraw Software

Design data directly sent to equipment

Remote control of equipment’s start and stop

Seamless integration of design and manufacturing

Built-in intelligent AI algorithms in the Riton Jawdraw Software

One-click generation of personalized key points and archwire shapes

No need for manual point selection

Effortlessly complete personalized design of removable orthodontic appliances

The platform is equipped with a task intelligent scheduling management system

Automatic sorting of processing tasks

Automatic matching of different specifications of wire bending systems

with corresponding equipment

No need for manual intervention

Helps enterprises build efficient production lines

Bridge the gap between doctors, technicians, and devices, achieving seamless online connectivity. Building a New Ecosystem for Digital Production of Removable Orthodontic Appliances

Riton 3D Printer Products

Leave a Message