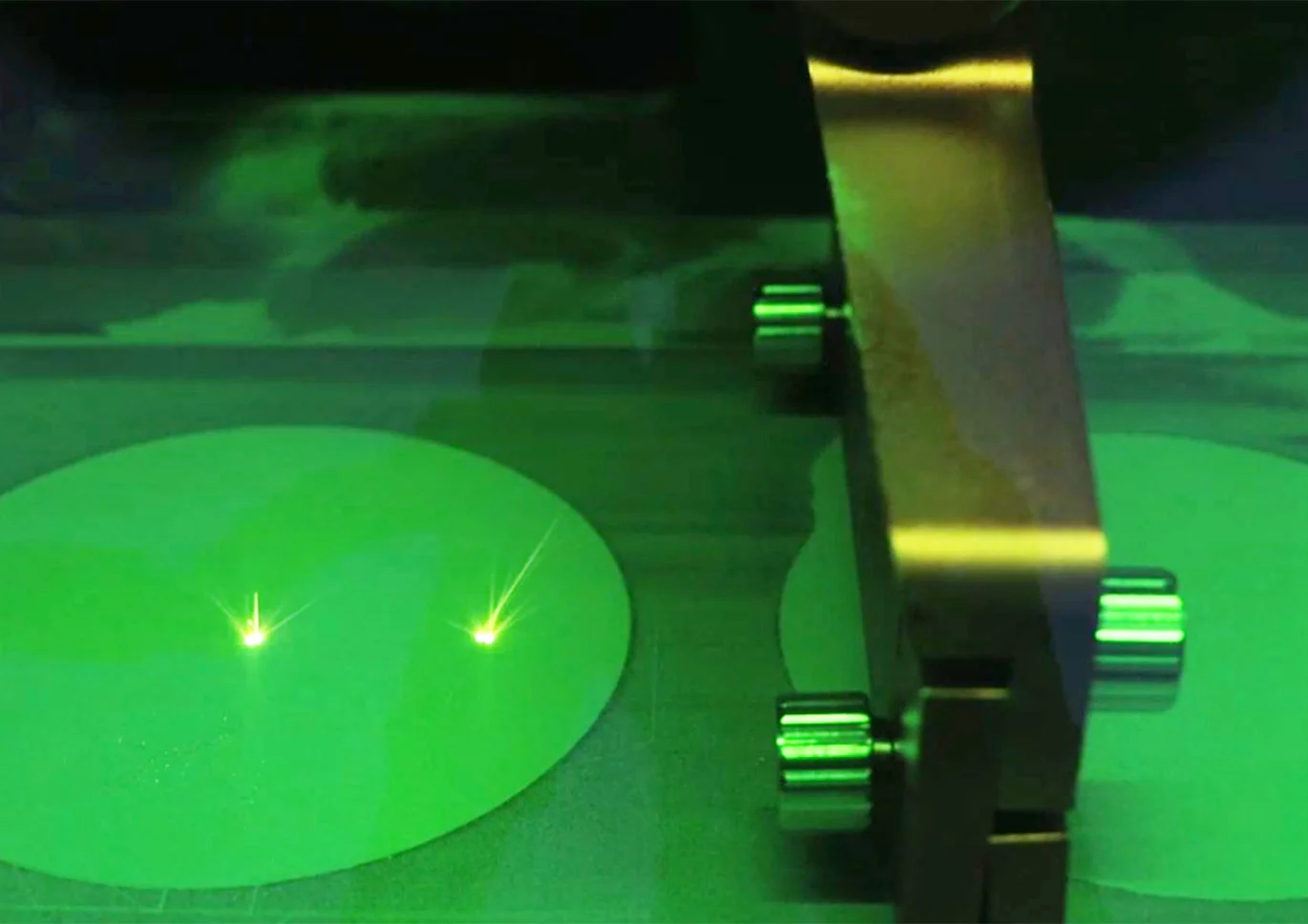

Laser Source | Single Fiber Laser |

Output Power of Single Laser | ≤500W |

Laser Wavelength | 1.064μm |

Scanning Speed | ≤14000mm/s |

Melting Area | φ150mm X 220mm |

Layer Thickness | 20-50 μm |

Protective Gas | Nitrogen / Argon |

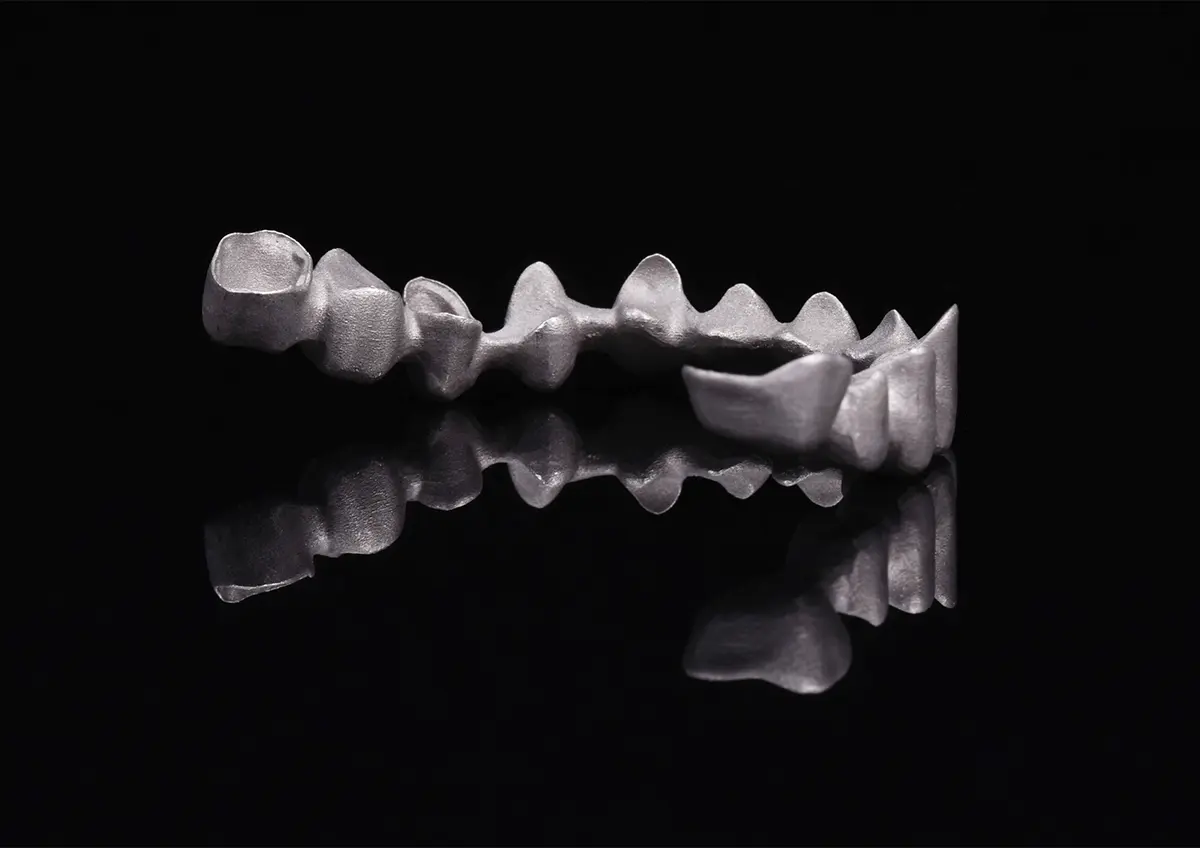

Productivity | Prints 200 metal crowns or 17 frameworks in 4.5 hours |

Power Supply | 3KW 220V |

Printer Weight | 500kg |

Printer Dimensions | 790mmx1010mmx1670mm |

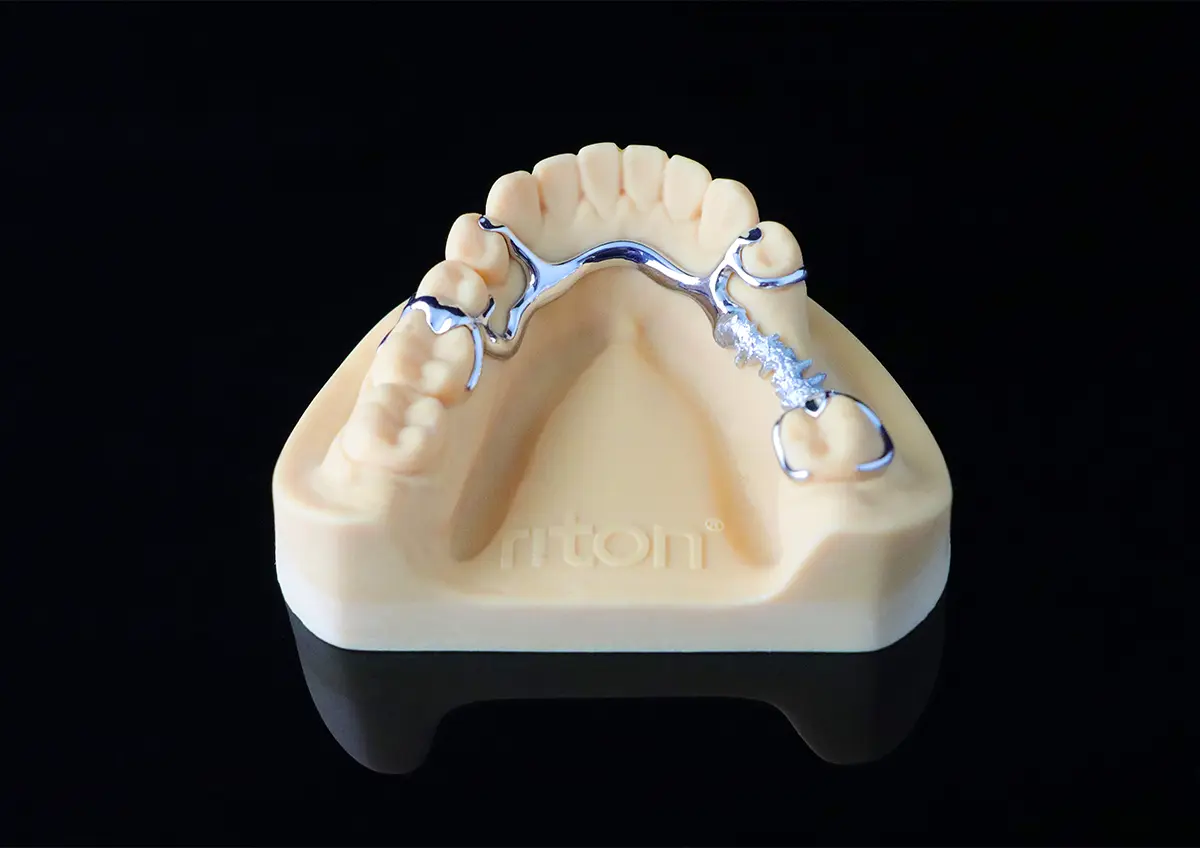

Melting Materials | CoCr Alloy / Ti Alloy |

Environment Request | Temp 15 ℃-35℃, Humidity≤95%, No vibration |

The overall size significantly reduced

Occupies only about 0.8m²

Adapts flexibly to space and site limitations

Helps optimize space utilization

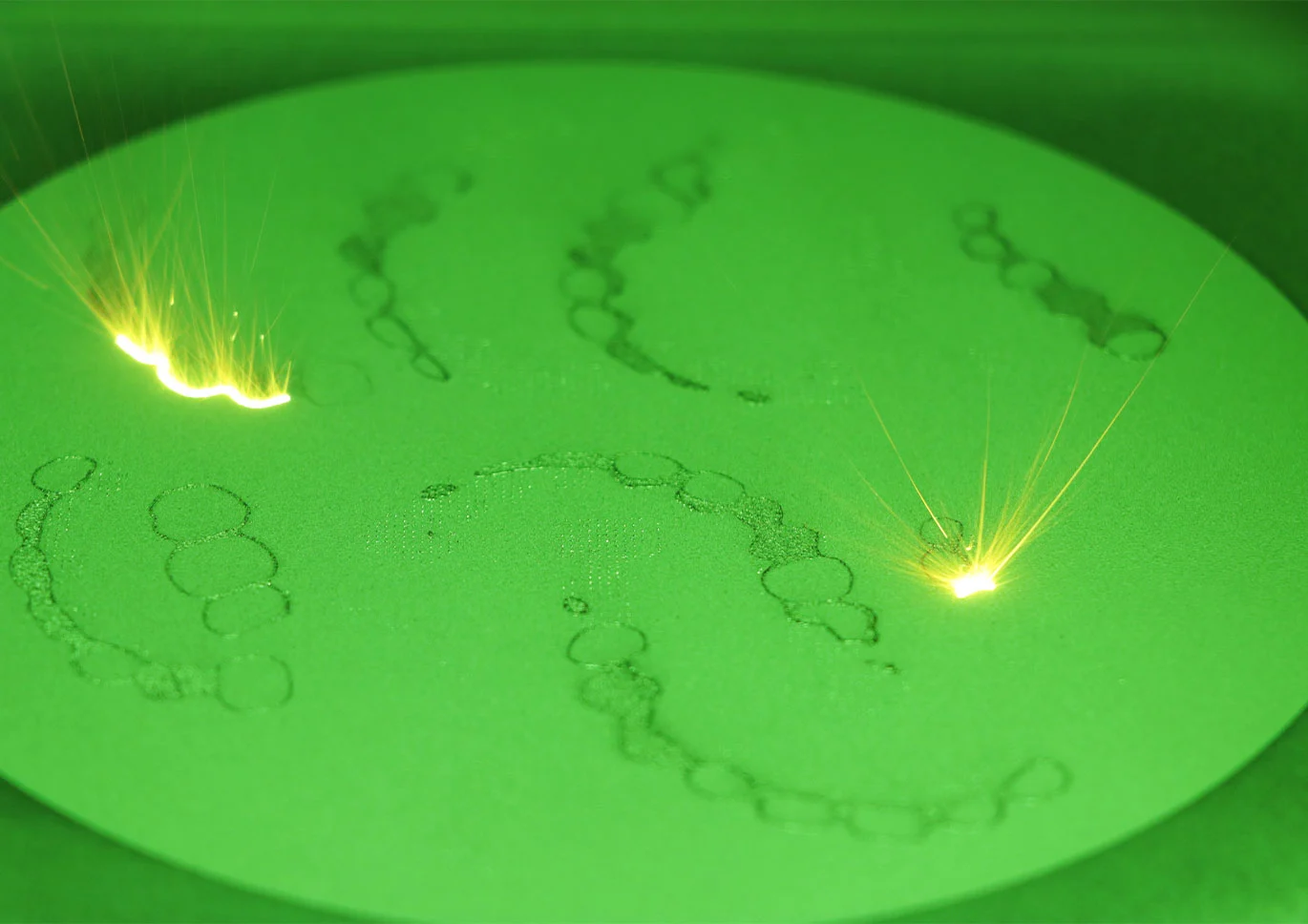

Optimized powder spreading process

Added features such as segmented variable speed, dual-cylinder lifting, and pre-powder spreading

Prints 200 metal crowns or 17 frameworks in just 4.5 hours

Efficiency increases by at least 30% compared to similar 3D dental equipment

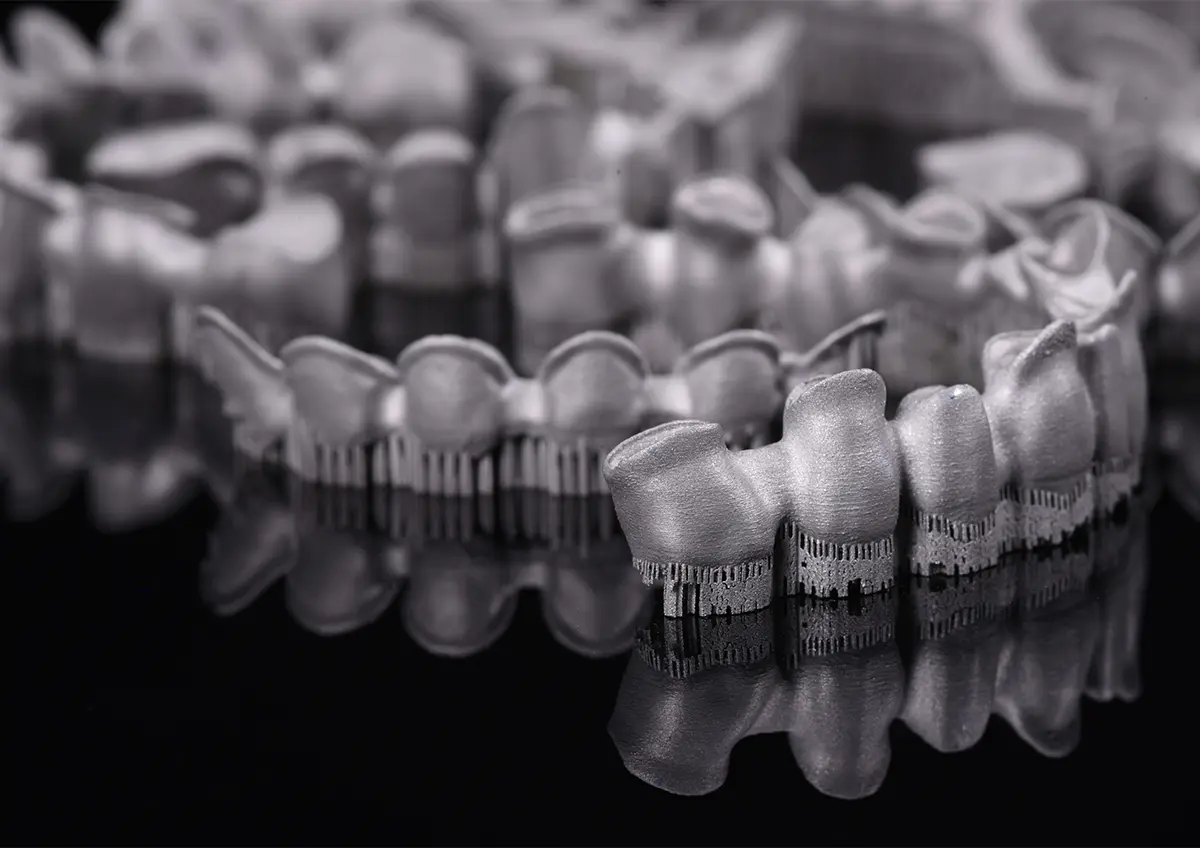

Optimized performance of the forming chamber

Adjustable optical path system

Spot compensation technology and multi-pass contour outlining technology

Island scanning strategy and regional filling technology

Multiple support composite structure technology

Together maintain the precision and quality of printed products

Hidden sealed structure design for moving parts

Separation of the equipment's circuitry from the powder forming section

Ensures long-term operational stability

Extends the equipment's lifespan

Automated deoxidation logic strategy + dual gas supply system

Reduces gas consumption

Eliminates the waiting time for equipment to refill with gas

Supports printing with various metal powders

Including Stainless Steel, CoCr Alloy, Ti Alloy, etc.

Dual Fiber Laser

Compact Size

Equipped with Both Efficiency & Precision

Automatic Inflation and Deoxidization

Adaptation to Multiple Metal Material Printing

Compact Size

Equipped with Both Efficiency & Precision

Automatic Inflation and Deoxidization

Two Modes of Powder Printing

Independent Circulation Pipes

Time-Saving and Handy Mode Switch

Equipped with Both Efficiency & Precision

Automatic Inflation and Deoxidization

Matched Full-Process Production Equipment and Software

Collaboration of Additive and Subtractive Manufacturing, More Efficient in Mass Production

Equipped with Dedicated Manufacturing Database and Fixtures, Ensure the Workpieces’ Precision

Wide Processing Adaptability

Support Secondary Milling and Processing of Workpieces

Reduce the Cost of Materials

Riton 3D Printers

Leave a Message