Metal 3D Printers-Start Your Creative Journey into Digital Dentistry

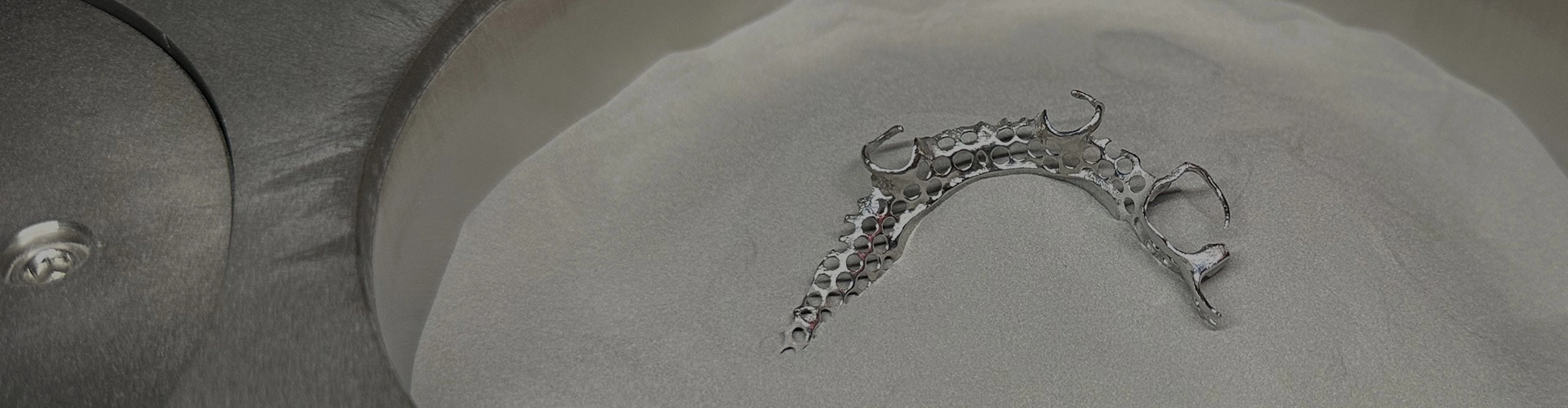

Riton's metal 3D printer is equipment that uses SLM (Selective Laser Melting) technology for metal additive manufacturing. The metal 3D printer machine is designed specifically for the production of dental metal restorations and serves as an excellent solution for dental companies to achieve digital production transformation and upgrade. As a leading metal 3D printer manufacturer, Riton DMLS machine streamlines workflows and provides dental professionals with a reliable and advanced solution for achieving superior outcomes.

MLAB

MLAB

Melting Area: Φ100 X 90mm

Printer Dimensions: 600 X 600 X 800mm

Production Efficiency: Prints 100 crowns or 7 frameworks in 2.5 hours

M-150 Series

M-150 Series

Melting Area: Φ150 X 120mm

Printer Dimensions: 790 X 1010 X1670mm

Production Efficiency: Prints 200 crowns or 17 frameworks in 4.5 hours

Powder Application: The metal 3D printer machine evenly spreads a thin layer of metal powder, typically 0.05 mm, across a build platform.

Laser Fusion: A high-powered laser in the metal 3D printer selectively melts the powder, fusing it into a solid shape based on a digital 3D model.

Layer Bonding: Each fused layer bonds to the previous one, gradually building the component.

Post-Processing: After printing, the part undergoes cleaning, removal of support structures, and heat treatment for enhancing strength. Surface finishing, like sanding, may be applied.

Riton 3D metal printer revolutionizes dental labs by enabling the production of highly precise, biocompatible restorations using TC4 titanium alloy. With advanced Selective Laser Melting (SLM) technology, the Riton DMLS machine crafts customized crowns, bridges, implants, dentures, and orthodontic frameworks with exceptional accuracy. Its compact design, like the MLab, fits seamlessly into lab spaces, enhancing efficiency. The use of TC4 titanium alloy ensures durable, corrosion-resistant restorations with excellent biocompatibility, is ideal for patient comfort and long-term oral health. Riton's metal 3D printing machine empowers dental labs to achieve digital transformation, delivering superior outcomes.

Riton's Metal 3D printing offers design flexibility, complex geometries, reduced waste, rapid prototyping, and high-strength, biocompatible parts using SLM technology, ideal for dental, aerospace, and industrial applications.

Riton's metal 3D printer supports TC4 titanium alloy, stainless steel, cobalt-chromium, aluminum alloys, and nickel-based alloys, enabling durable, biocompatible dental restorations with Selective Laser Melting (SLM) technology.

Contact Us

Leave a Message