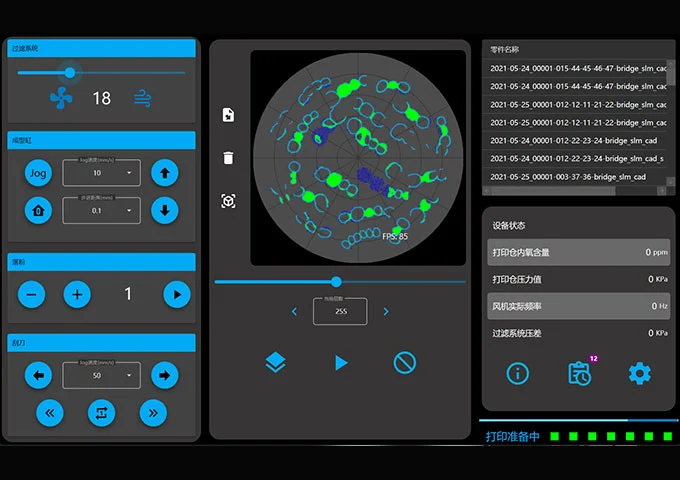

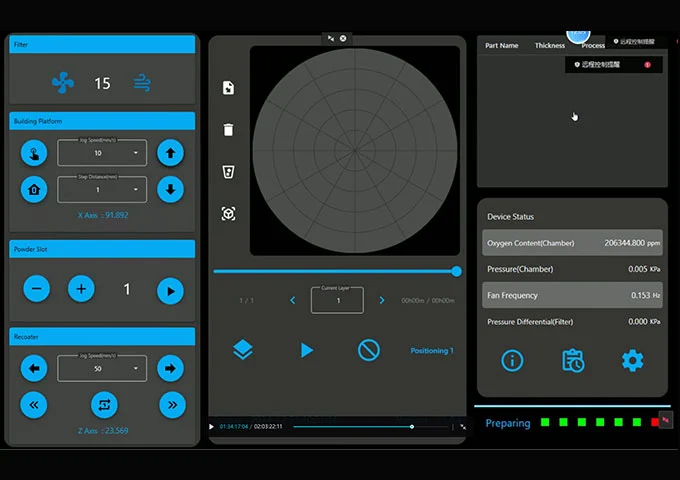

Real-time monitoring of equipment operation and printing status

Intuitive display of component states and printing information

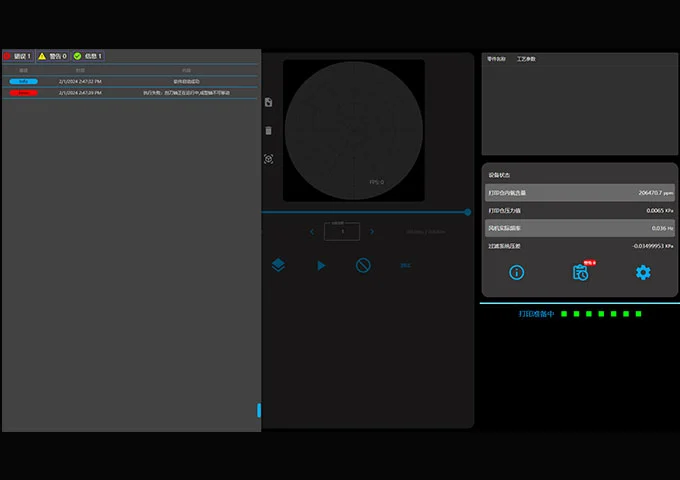

Rapid fault diagnosis

Full understanding of equipment status

Equipped with printing editing functions

Supports printing only the required layers

Instantly removes unnecessary printed parts from the preview interface

Breaks traditional printing constraints

Freely defines printing content

Real-time tracking and recording of printing progress in the background

In case of unexpected situations (such as sudden power outages) causing printing interruptions

Once the equipment returns to normal working status

The software will automatically recognize the pause point of the printing task and continue printing

Ensuring continuity of the printing process and completeness of the printing task execution

Clear and straightforward functional partitions and button functions

Easy to operate printing procedures

Reduces learning costs

Automatic recording and logging of each layer's printing status

Key information can be filtered and viewed with one click

Ensuring traceability throughout the entire printing operation

Protection of Production

Dedicated personnel for explanation and demonstration, offer help for quickly mastering software operation procedures

To ensure each printed work is perfectly presented

Quick response to assist in solving technical problems

Leave a Message